The Man’s heart, part two: Moving between two worlds

I’ll say right now where my machine expertise lies: old, beated down, barely working things that I can fix or at least mutate into some other whirling, spinning thing. Bicycles, covered in grease, hacked apart and put back together. Old Volkswagens. Unidentifiable hunks of wires and gears. Ethereal computer magic-box art making? Not so much.

When it comes to 2D art, I seldom work in the computer. If at all, I work only in photoshop, which i am rather good at. But never illustrator.

So when I had this idea of using rapid prototyping machines to make MY machine, I was simultaneously excited and dreading the point where i would have to be working on the computer. Im a ink flinger, a grease monkey, a wrench head- not a mouse jockey. Or a tablet jockey, in this case.

(image: the completed cam follower, with the cam. They rust like this about 5 seconds out of the waterjet)

More behind the jump- go on, read it. Everyone is doing it.

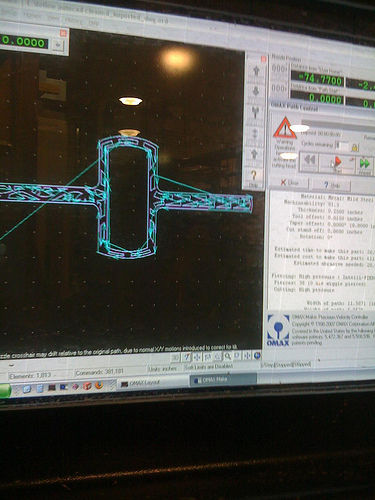

(image: tool path for water-jet action!)

To make the changes I wanted- namely, making the parts more ornate- I needed to bring them from Solidworks (a program I know utterly nothing about) to Illustrator, and then to then back into CAD so it could be read by the OMAX water jet cutter. Which amounted to no end of headaches in corrupted files, artifacts, and changing file formats.

Had I not wanted to get artsy-fartsy, I could have just taken the free CAD file from KMODDL, stuck it in the OMAX, and cut. I want that to be pointed out- I, Meredith Scheff, made it much harder than it needed to be. While it was a gigantic pain in the ass for me; for any reasonable, sane person that didnt need their machines all fancified, could have done this fairly simply. Plust, the feeling of seeing something in the meatsphere where it had only existed on the screen? Pure, simple, joy. The water jet works in a submerged state, so, metal goes in, parts come out. Amazing.

(image: the cam follower, as it comes out of the water bath)

And that is seriously, seriously cool. The ability do basically download and print parts- whether on your own home-brew 3D or 2D printer, or have it outsourced to one of the many internet laser cutters- is a great leap forward in Making stuff..without a 1500 SF warehouse. I am lucky enough to have a friend with access to these tools, but they are becoming more and more available through the internet and community workshop spaces.

That’s a pretty long post for today, so electronics will have to wait for tomorrow.

Next up: electronics, moving parts, and…will it work?