Sew-through Soft Circuits

Your mostly-humble narrator

I've had an off-and-on love affair with soft circuits since I became aware of them. Unfortunately, all the pre-made boards for soft circuits are clumsy (being traditional hard PCBs) and finnicky (hard to keep a good connection) to use.

Being a good little hacker, I decided to make my own.

Way more after the jump…

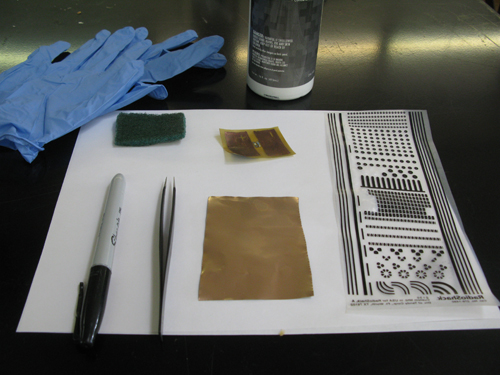

Here's all the stuff I used. From left to right-ish: Gloves, scotch brite to pre-sand the boards, a board I made earlier (credibility), Etchant (ferric chloride), rub on pad/trace patterns, nice new sharpie, super tweezie-tweezers, flexi PCB. Not shown: a sponge cut into 4ths to etch with.

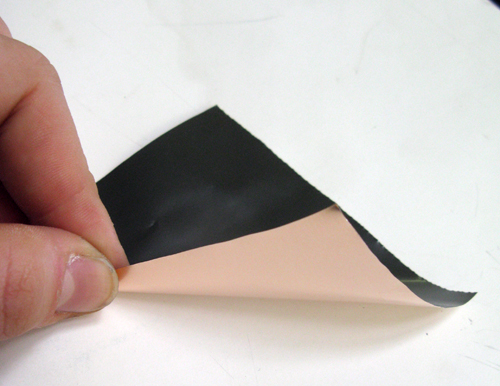

The material I used was DuPont's Pyralux Copper Clad Laminate (whew, a mouthful). Fellow Noisebridge pal Eric Boyd had requested a 'sample' from DuPont- and recieved a whopping 10 square feet of the stuff. The type he requested is super thin and flexible, as you can see. It comes with one side totally blank copper laminate.

I like my ground planes like I like my men: flexible, square, and I can't believe I'm making this joke.

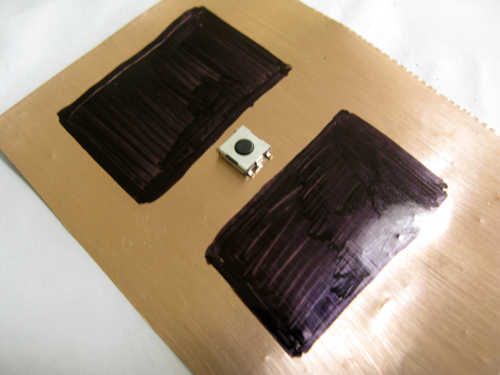

I've already made a few boards like this for my LEDs. This time I need a button. For, you know, pushin', turnin' stuff on. You know. A button. This is the only SMD one Radio Shack carries.

The most important difference with this technique/material is the ability to sew right through the board with conductive thread. Design wise, that means you want to plot out nice biiiiiiiiig pads for your machine to run through. You can trim the material afterwords.

Leave about an 1/8 inch area on either side of your part(s). I wanted to be able to trim them pretty small if I felt like being sadistic. I usually leave a nice big '+' and '-' open area in the sharpie'd area for ease of ID later. This time, however, I forgot. Boo.

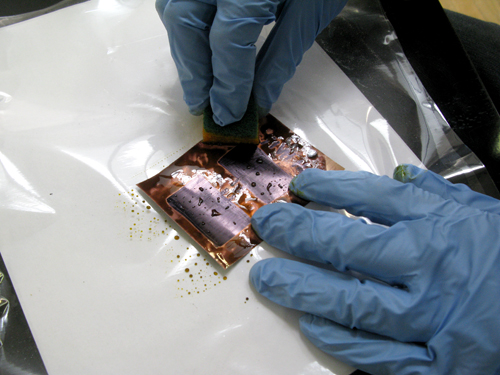

PCB's are notorious floozies. Make sure to wear protection when handling them. (…)

Just kidding! Wear gloves to protect the boards from your meat-bag finger oils. Even a little touch can ruin your etch.

(LOLz)

This is the completed board, before etching, with uh..notations. Ya, notations.

I used the sponge method for etching. It's way faster and easier, which is great, because I'm super lazy efficient.

Exiting!

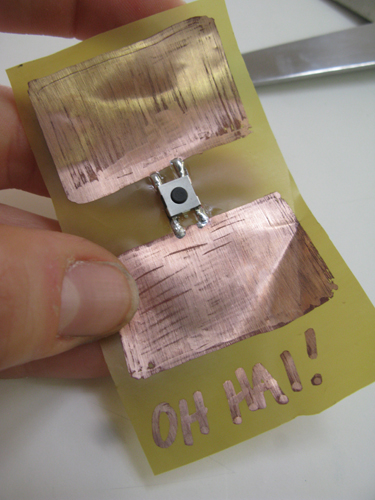

Etched and cleaned circuit. I didn't bother to get the edges, as they're going to be trimmed off anyways. See note above re: efficiency. You can use rubbing alchohol to get off the sharpie.

Also, make sure to dispose of the etchant fluid correctly, so the members of your hackerspace don't kick your a**.

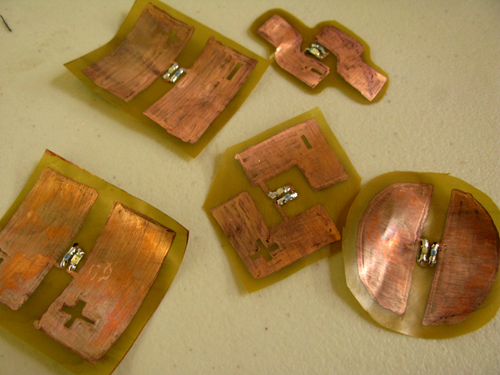

Here's the board trimmed and with my button soldered on…the wrong way. AS A DEMO. Demo is: I did it wrong. Then I fixed it.

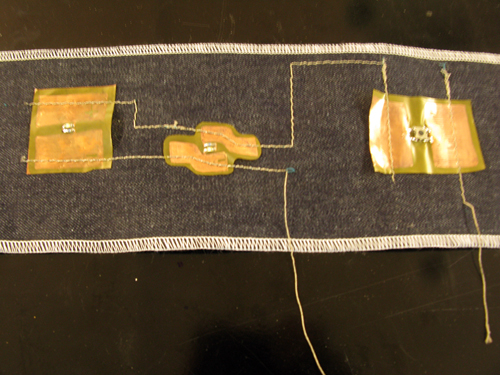

Where these boards really shine: I can sew right through on the machine, and since there are so many contact poins, the connection is really good and tight. Make sure to set your stitch length as long as possible to prevent tearing. Zig zag would be better, but our machine doesn't do that. You can see my button already sewn on to the right- I was too excited and forgot to take a photo. This is a SMD LED board make previously.

Since you are using the machine, It's really easy to make curves or sharp turns to complete your circuit. To attach a new 'trace', simply sew back over the thread it needs to connect to- which has the added bonus of making it a lock stitch.

That's it! Here are some more shapes I have experimented with. I am trying to find an economical way to have these proffesionally done so I can sell them to you, the reader.