DIY Powder Coat/Curing/Reflow Oven

I found a very clean, barely used toaster oven at the dump. I originally intended it for the kitchen but it turned out that the toast function timer was bad, so off it went to the workshop. I tried using it a couple of times for curing paint and epoxies but even at the lowest setting it would get too hot. So I decided to upgrade the controller to something a bit most precise.

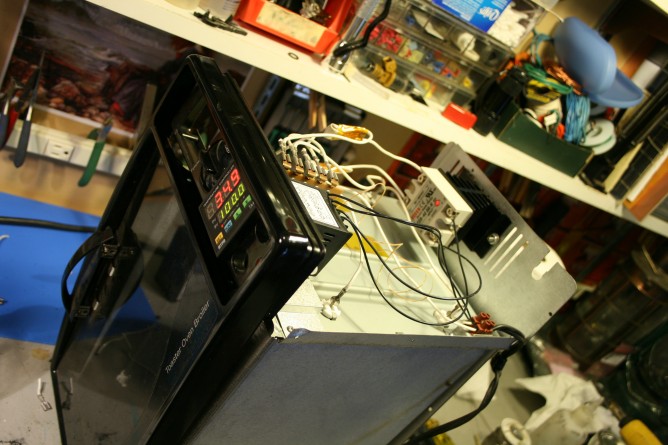

I found the perfect temperature controller on Amazon and ordered it along with a solid-state relay and thermocouple temperature sensor. I stripped the circuit board from the oven and cut a hole in the front panel for the controller.

I tried mounting the solid state relay inside the oven, but it got hotter that I was happy with even with the heatsink. It still worked fine, but I felt it wouldn’t work indefinitely at that temperature. I remounted the heat sink and relay so they sandwiched the back plate of the oven and that worked great.

The oven works beautifully and holds a temperature down to 100 degrees Fahrenheit with no trouble at all. It can be used for curing epoxies, powder coat paint, solder re-flow, and maybe even heat treating of knives, though that may take it’s toll on the overall life of the oven! Not bad for about $30 in parts and an oven from the dump.

That is a great little oven build. One of the downsides of common home ovens is the lack of a PID controller, resulting in unstable temperatures.

I documented a very large powder coating oven build here: http://www.powdercoatguide.com/2014/09/how-to-build-powder-coating-oven.html