WW-II Vintage Homemade Welder

I found this welder on Craigslist for hundred dollars. It’s made with a World War II surplus aircraft generator and the engine from a 1946 Austin Dorset. It’s a 200 Amp DC welder with a four-cylinder pushrod engine. This is a first look at it and there will be more videos as I get it running and clean up this piece of DIY history. Stay tuned.

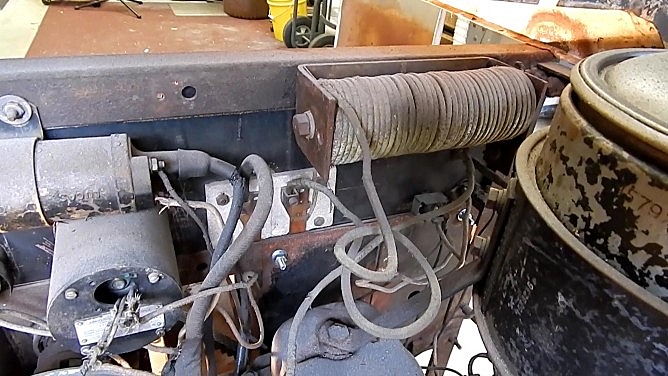

I estimate the welder to weigh about 700 pounds. It has a 200 amp Delco Remy P1 aircraft generator, powered by a 1946 Austin Dorset four-cylinder pushrod engine. In addition it has a 12 V generator for the charging system, a voltage regulator, and electric starter.

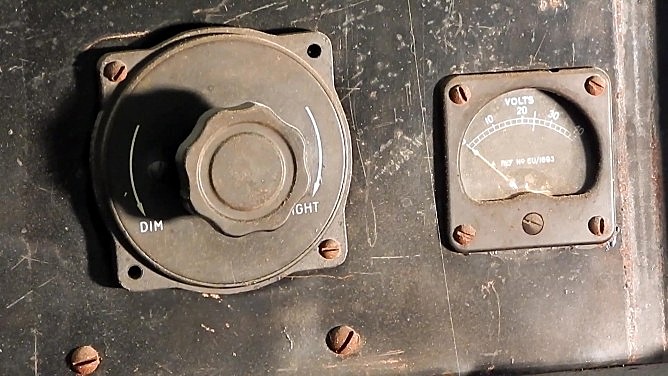

The controls are minimal. There is a rheostat to control the field current to the generator to set the welding amperage. In a voltage gauge for same.

There’s an ignition switch, starter switch, and choked to control the engine.

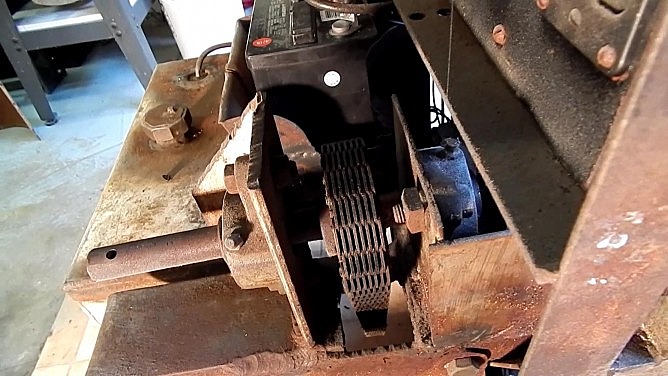

The generator is driven by a timing chain rather than a V-belt. This means no slipping under heavy load!

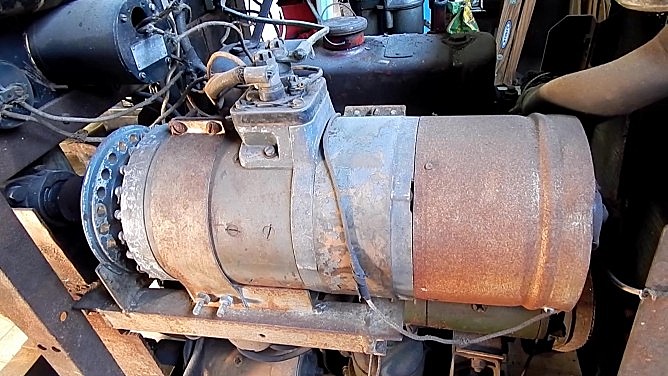

This is the Delco Remy aircraft a generator. As I said earlier, it’s 24 V 200 and DC.

The coil in the upper right part of the image is an arc stabilizer. It’s an inductor that smooths out the welding arc. At the end of the arc stabilizer there are a pair of contacts, when you begin to weld the contacts close and energize a solenoid that opens the throttle and brings the machine up to welding speed.

There’s a 12 V fan at the back of the generator, my understanding is that these generators if provided with cooling like this fan, are continuous duty machines.

I have not gotten the welder to start yet, I did weld on a set of wheels so I could move it around the shop more easily. Initial investigations show that there is no spark and I suspect the Lucas electrics. I do plan to get it running very soon and I’ll be back with pictures and videos of the machine running and welding.

Open the distributor cap and clean the points with a points file.

Check that the coil is getting power from the battery with the switch on.

She’ll start right up.

All of the electrics have the word LUCAS on them, I suspect it may not be that simple! 😉

I think I can see one problem, the coil HT lead insulation is perished just by the terminal boot. Quite likely there will be some natural rubber cable insulation on something this age, and it will disintegrate if disturbed at all. As mentioned check the condition, gapping and timing of the points. Lucas kit of this vintage was very good quality, chances are the coil etc is still in good order.

Actually, it is! This is a simple system. Points closed, low voltage circuit energizes coil, points open, collapsing magnetic field in the coil induces a high voltage in the high tension coil.

That ignition coil is jut an autotransformer.

A condenser across the points minimizes arcing across the points. If the points are badly burnt if the running engine misses badly, the condenser should be replaced.

Over time oxidation builds up on the points of an engine that has not run in a long time. Cleaning it off with a point file (looks like a steel version of an emery board)(don’t use an emery board) just takes a few swipes.

Also the points should be adjusted. The gap should be intact from when the motor last ran unless someone messed with it along the way. You can set points by eye – rotate the engine by hand so that the point block is at the top of any lobe of the the four-lobed cam (one lobe for each cylinder) and set the gap to the thickness of a thin dime.

There will be a lubricating felt wick – one or two drops of motor oil go there. Too much oil and it will get flung off and foul the points.

There is a pigtail wire that connects the points thru the body of the distributor that goes to the coil. These pigtail leads can break or wear thru their insulation (the advance unit rotates the plate the points mount on, so the wire sees flex and a weak spot is where it goes through the grommet), so check that as well.

Points systems are cave-person crude, so it only takes a few minutes to troubleshoot and put things right.

If, as someone said, you need high-tension coil or spark plug wires, these are universal and you can replace these yourself quite easily and for a few dollars.

Good luck.

Hi Jake, I’m doing a similar project with a 5500 watt generator I picked up for $50. The genset already had a wheel set but the tires were dryrotted. I went with the flatfree wheelbarrow tires from Lowes and they have worked well. I’m a longtime fan of the Steampunk Workshop, keep up the cool stuff!

Great job!