Warehouse 13 1/8

It all started with a bad snowstorm when the two metal sheds in our backyard collapsed under the snow load. I contacted our insurance agent and we were indeed covered. However there was an issue with getting quotes for the sheds’ replacement. We bought these two metal sheds from Home Depot, they were about three or $400 each, but they took my wife and I two days each to assemble.

I couldn’t find a company that would sell me the sheds installed on-site, so I called my insurance agent and I sent him a quote for two wooden sheds which were only $60 to deliver but cost almost twice as much as the metal sheds. The quote was for about $2300, and I thought this a very reasonable compromise. He forwarded the quote to the insurance company and the insurance company rejected it because the sheds were “better” than the original sets. They completely ignored the issue of the labor to build and install them.

Rules. They have their rules, you can’t get something “better”. Well I am very good at the game of rules. I found the assembly manual online for the exact make and model of the sheds that I had lost. Then I took it to a handyman company in the most affluent neighborhood that I could find and I asked them to give me a quote for the labor required to assemble two of these sheds. I was totally up front with them and they chuckled and made me out a quote for the amount of labor as stated in the instruction manual plus mileage and travel time!

I combined that document with a quote from Home Depot for exact model replacement sheds and forward that to my insurance agent. Instead of the $2300 that I had proposed and they rejected, they ended up paying out $3700. The extra $1400? The price of being a dick.

In addition to losing the sheds, we also lost the temporary building that I used to garage the roadster and store some materials. It was the first structure of it sort that I had used and it lasted about three years, but I had to knock the snow off the roof every time it fell. So with the windfall from the insurance settlement, we decided to build a real warehouse.

In addition to losing the sheds, we also lost the temporary building that I used to garage the roadster and store some materials. It was the first structure of it sort that I had used and it lasted about three years, but I had to knock the snow off the roof every time it fell. So with the windfall from the insurance settlement, we decided to build a real warehouse.

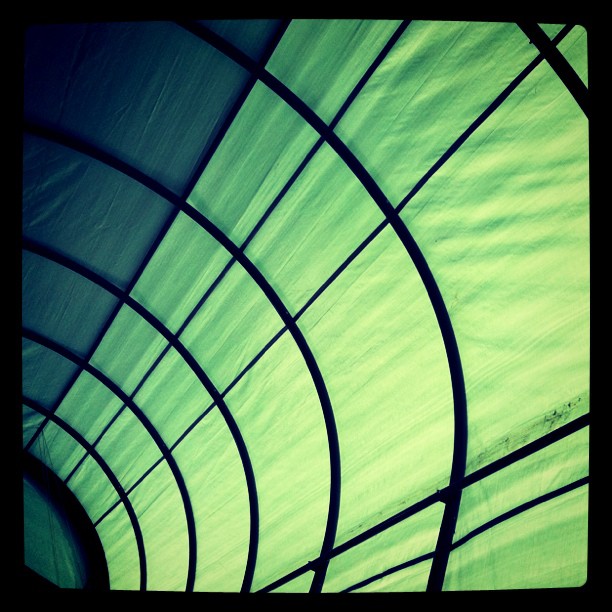

I looked online and eventually settled on this 14′ x 36′ x 12′ high four season temporary building. The rounded top means the snow slides off and I don’t have to go out and knock it off the roof every time. Assembly was a little bit of a challenge to do all by myself but eventually I found that putting a piece of plywood on top of our minivan and using that as a build platform did the trick. I assembled and bolted together the steel tubing, staked it to the ground, and made sure everything was vertical and level.

The next step was to strap the tarps onto the ends and then toss ropes over the top to pull up the body of the temporary building.

It took about one whole weekend to get everything assembled (about a quarter of the labor required to assemble those damn sheds!) covered, and straight.

The new building is much larger than the old building and the sheds combined. I covered the floor with a heavy-duty tarp that we used to use to cover our pool. It’s important that you never store a car over open ground. Moisture from the soil will condense on the frame and body of the car on a regular basis, and this will cause it to rust badly and quickly.

The new building sat in the same place as the old white tent, but even though it was bigger it is less obtrusive because of the dark green color.

The next step was to build shelves for the interior. I framed them with two by fours, supported them with 4 x 4’s, and covered them with oriented strand board for the shelves. They are 12 feet long and 3 feet deep and the 4 x 4’s are 12 feet tall.

Everything that used to be in the two metal sheds and the white tent now fit neatly into the new warehouse.

In addition the high ceiling allows me to hang many items from EMT conduit stringers that are mounted on pulleys. These I can lower to access when I need to.

I pressed to some of the lighting fixtures that I’ve collected over the years into service to light the interior of the warehouse.

And I’ve installed a nice pair of JBL speakers and an amplifier so I can listen to music while I’m working out there.

The temporary building has held up exceedingly well after three years and I expect it to last many many more. It does get a bit hot in the summer so the next enhancement will be some sort of exhaust fan near the peak of the roof.

A solar panel wired up to a fan works wonders on a hot sunny day:

http://autoweek.com/article/wait-theres-more/using-cheap-junkyard-car-parts-make-solar-powered-attic-ventilator

Jake, why not use your custom built swap-cooler? I don’t live in your part of the country, so I have no idea of the efficiency of running one of these in the Boston area.

They don’t work well here, too humid. In fact I had never even seen one until I traveled to the southwest.

Jake:

For this post and many others–you’re kinda my hero. I aspire to being this organized, pro-active, and practically creative in my own life. Thank you!