Guest Post: The Ferris Hybrid

By Brandon Boyer

In 1901, Queen Victoria of The United Kingdom passed away. The same year Ferdinand Porsche developed the first ever hybrid vehicle, the Löhner-Porsche Mixte Hybrid. Today the spirit of Victorian ingenuity and know-how lives on. In Chilly Big Rapids Michigan, a small group of international engineering students are working towards their common goal, competing in the SAE International Hybrid Competition in New Hampshire later this year.

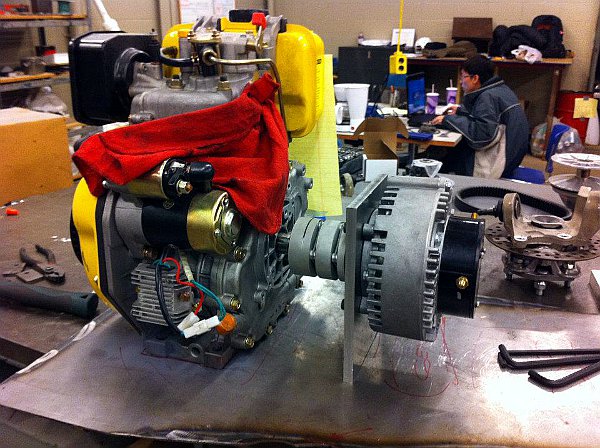

Their unique design strays away from conventional hybrid technology, fore-going a gasoline engine for a diesel engine that utilizes clean burning bio-diesel. The Engine output has been optimized over their original design to “decrease fuel consumption by 50% while increasing power output by 10%” says Bassirou Dieng, Team Vice President. The generator connects to the team’s other surprise; a pair of high output capacitor banks.

Former team president Bergen Lorentz describes the reasoning behind this unusual choice in storage mediums. “Capacitors are more power dense, so they are able to discharge a much larger amount of energy all at once, and that energy can be charged just as quickly as they are discharged, as opposed to traditional batteries that have a maximum charge and discharge rate.” Weight reduction was also a factor in the decision “The capacitors are about sixth of the weight per watt/hour of storage compared to traditional batteries, which allows us to cut down on our weight substantially.”

While the advantages are immense, working around the capacitors while they are charged presents a unique set of safety concerns. Since the capacitors operate at 56 volts they can penetrate human tissue and discharge their entire charge into a person. The competition requires that the team has protective safety equipment that is inspected and verified each year so that they can safety overcome these concerns.

The entire power plant is connected to a frame made of 5150 Chrome-Moly steel. The frame was designed and verified digitally by students before fabrication occurred. Current President and Team-Welder Brian Ohlrich took charge of welding and fabricating the frame. “I’m happy say that this frame will be substantially lighter and stronger than our previous frame, we were able to modify our design to accommodate thinner-walled tubing while still meeting our strength requirements and allow for better overall weight distribution.” The frame was welded using a combination of Gas Tungsten Arc Welding (TIG) and Solid-Wire Gas Metal Arc Welding (MIG).

Over the next several weeks the team intends to finish the internal components of the vehicle and wrap the body in a layer of fiberglass. Then track testing and tuning will begin. “Various members of the team will have to drive during the events; the rules are set up that way to prevent driver skill from becoming too great of a factor.” Said Lorenz

The primary obstacle at this point for the team is time and money. “The ultimate goal is to have the car finished at the beginning of April, that would allow us plenty of time for testing and fine tuning” said Ohlrich. Money is also a factor as the team is trying to compete on a shoestring budget, “We are trying to build the car for less than $10,000, and some of the other teams have close to ten times that in their budget.” The team’s ingenuity is burning bright; parts are coming from scrapyards, fabricated from scrap and improvised whenever they can. “Our hopes are high, we may not win, but just being able to compete is an accomplishment.”

If you are interested in following the team’s progress or in sponsoring the team please refer to the following pages:

Facebook: https://www.facebook.com/Ferris.State.University.Formula.Hybrid/info?ref=ts

Twitter: @FerrisHybrid

Email: ferrisformulahybrid@gmail.com